Tube Settlers Vs. Plate Settlers: Comparing Lamella Technologies

The sedimentation process in both water and wastewater treatment is a physical process which relies on gravity to settle and remove suspended solids. Advanced solids settling processes typically utilize lamella, commonly referred to as tube settlers or plate settlers, to reduce the vertical distance solids particles must fall until hitting a “settling surface”. Higher flow rates, better effluent quality, and more compact sedimentation basins can all be achieved with both types of lamella sedimentation equipment. Although both operate on the same principles of solids settling and can be used as basis of design in many cases, there are several notable differences between the two technologies.

Characteristics of Tube Settlers and Plate Settlers

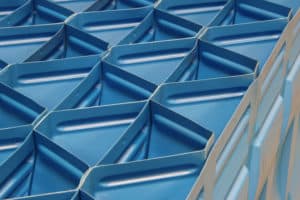

Tube settlers utilize multiple adjacent tubular channels that are sloped at a nominal 60° angle and combine to form an increased effective settling area. The size and shape of the tubular channels vary by manufacturer. Brentwood’s tube settler design features a trapezoidal shape created by thermoforming PVC sheets. You can learn more about our design process by reading our Thermoformed vs. Extruded Tube Settlers blog.

In contrast, plate settlers use a series of inclined plates, typically constructed of steel, which are spaced two to three inches apart from each other on a 55° to 60° angle to form an increased effective settling area. As a result of these design differences, typical design parameters for these two types differ.

Comparing Design Parameters

It is important to note that there is a difference in application rate (flow rate/coverage area, expressed in gpm/ft²) between tube settlers and plate settlers as a result of different effective settling area terms used, despite settling principles being similar for the two technologies.

To provide a more direct comparison, the application rates of tube settlers can be converted to an equivalent “plate” application rate by taking into account the projected surface area of tubes (see Figure 1).

As illustrated, the equivalent maximum “plate” application rates of Brentwood tube settlers are in the same range as a generic plate settler, which has an average application rate of 0.30. IFR6041 tube settlers are the most comparable to plate settlers in regard to coverage area because settler length is similar. However, Brentwood’s other tube settler modules are capable of treating required flow just as effectively with appropriate coverage area. Tube settlers also eliminate cross-flow and eddy currents, which makes flow hydraulics more stable and efficient.

In addition to varying design approaches, there are other advantages and disadvantages to consider when comparing tube settlers or plate settlers for your application.

Making a Selection

When selecting lamella sedimentation equipment, a cumulative decision should be made based on performance and long-term economic impact. Tube settlers may not match the lifespan of plate settlers, but their lower initial cost and ease of installation can be enticing to a plant of any size. Their lightweight and easy to maintain characteristics, along with superior structural capabilities compared to other tube settler options on the market, make Brentwood’s equipment a clear choice.

| IFR6024 | IFR6030 | IFR6036 | IFR6041 | |

|---|---|---|---|---|

| Maximum Tube Settler Application Rate (gpm/ft2) | 2 | 2.5 | 3 | 3.5 |

| Projected Surface Area (ft2 / ft2 Plan View Area of Tubes) | 5.84 | 7.83 | 7.71 | 9.56 |

| Equivalent “Plate” Application Rate (gpm/ft2) | 0.34 | 0.32 | 0.39 | 0.37 |

Tube Settler Advantages

- Lightweight PVC results in easy installation and does not require heavy lifting equipment

- Lower capital cost due to materials of construction

- Applicable in shallow tanks with underflow velocity concerns

- Twenty to twenty-five year service life, provided proper maintenance is performed

- Only PVC tube settlers are replaced at the end of their useful life; typically supporting structures and effluent

troughs can remain - Tube settlers are strong enough to walk on top of for proper maintenance

- Highly customizable to accommodate varying basin configurations

Tube Settler Disadvantages

- Maximum module vertical height is 41 inches, resulting in a maximum application rate of 3.5 gpm/ft²

- PVC must be protected from extensive UV exposure. Brentwood tube settlers do contain UV inhibitors. AccuGrid

protective surface grating is also available for additional UV protection.

Plate Settler Advantages

- Less limitation on depth

- Longer lifespan due to material of construction

Plate Settler Disadvantages

- Two to three times higher capital cost

- Higher installation cost due to required heavy lifting equipment

- Deeper basin requirements to accommodate underflow velocities

- Risk of corrosion in certain environments (certain industrial wastewater applications)