Water and Wastewater System Components

Tank Enviro Systems supplies the market leading range of Brentwood Polychem system components.

Brentwood’s Polychem chain and flight systems are comprised of the finest quality components available in today’s market. Reliably constructed and economically designed, these products function efficiently as part of any clarifier system. We offer replacement components for competitors’ equipment and perform on-site inspection for evaluation of wear conditions through our complete aftermarket sales service and retrofit program. Our dedicated engineers and field service personnel are available to discuss any questions customers may have on their chain and flight sludge collector equipment.

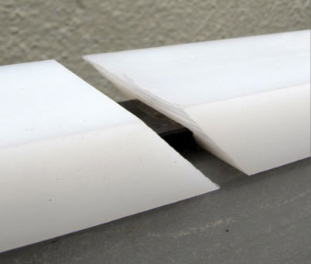

Flights

Brentwood offers more flight scraper options than any other chain and flight manufacturer, this provides sludge collection solutions for any water or wastewater application. In addition to industry standard c-channels, Polychem’s flight offerings include the proprietary Ultra, Ultra Plus, Box, and E-Flight profiles for heavy loadings and deep sludge blankets. The Ultra Plus and Box flights provide sturdy and reliable options for wide tank applications, and the E-Flight is the ultimate solution for processes that require a taller scraper flight.

All Polychem flights feature a flat-face design to eliminate the potential for recirculation of solids and are fabricated from UV-inhibited isophthalic polyester resin. They offer a flexible solution that accommodates tank wall variations and can be supplied pre-drilled or -notched to account for floor and return rail locations.

Complementary Components

Sprockets

Brentwood’s Polychem sprockets are molded from a specially selected, high-strength Nylon material that outwears and outlasts UHMW-PE and polyurethane sprocket alternatives. All sprockets are equipped with standard integral teeth to maintain tooth alignment and are designed for use with Polychem collector chain.

Head Shafts

The Polychem non-metallic telescoping head shaft was invented and installed as part of the first 100% non-metallic system in 1984. At that time, the industry was just beginning to test plastic as a lighter, corrosion-resistant alternative to steel. Today, Polychem non-metallic head shafts have become the water treatment industry’s gold standard.

The head shaft’s unique assembly does not require crane installation and is virtually maintenance free. Two fiberglass end tubes with internal bearings and keyways overlap a center tube and are joined together with torque interlocks and set collars to form one robust, easy-to-lift shaft. Since its introduction, the Polychem telescoping head shaft design has been utilized in over 12,000 systems worldwide.

Stub Shafts

Polychem idler stub shafts are the lightweight alternative to traditional full-width steel shafting and cast iron wall bearings. We offer two base diameters and lengths to accommodate sprocket centerlines from 9 to 29 inches off the wall, allowing customized stub shafts to fit various tank sizes, system loadings, and existing structural conditions.

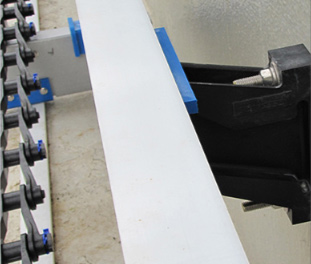

Collector Chain

Brentwood’s Polychem NCS-720-S Collector Chain is among the strongest 720-series chains on the market. Precision moulded from durable, glass-reinforced polyester, this lightweight chain withstands high sludge loadings in corrosive environments. Our collector chain can also be protected with barrel wrap for high grit or highly caustic conditions. By reducing barrel wear, the chain lasts longer and performs better.

Drive Unit Assembly

Brentwood supplies drive units that are custom configured for each collector based on system requirements and regional and environmental conditions. Each system utilizes a motor and gear reducer and optional components such as over torque protection to prevent drive system failure, a drive chain tightener to maintain tension, and a chain guard to protect rotating equipment above the deck.

Resources