Understanding Industrial Pumps for Wastewater Treatment

Optimised pumping solutions for sustainable treatment systems.

Effective wastewater handling depends on choosing the right pump for the job — wrong choices can lead to poor performance, frequent maintenance and increased operational costs.

This guide explains the main pump types relevant to wastewater environments, key selection factors, secondary considerations that can influence performance, and how to keep pumps operating efficiently over time.

What are Industrial Pumps and Why They Matter

Industrial pumps are mechanical devices designed to move fluids — in wastewater systems this includes water, sludge and other effluent streams. The right pump will ensure consistent flow, minimise wear, and reduce energy and maintenance costs.

Common Pump Types Used in Wastewater Applications

Each pump type has strengths and limitations, and must be matched to the liquid characteristics and system requirements.

Centrifugal Pumps

These pumps use a rotating impeller to move fluid and are the most common type used in wastewater treatment.

Typical Wastewater uses:

- Raw sewage transfer

- Pump stations

- Effluent handling

- Sludge and solids-laden liquids

Screw Centrifugal Pumps

These combine features of centrifugal and positive displacement pumps, using a screw-shaped impeller.

Typical Wastewater uses:

- Wastewater with high solids content

- Sludge transfer

- Screening plant discharge

- Industrial effluent

Recessed Impeller (Torus / Vortex) Pumps

These pumps allow solids to pass without contacting the impeller directly, reducing wear and clogging.

Typical wastewater uses:

- Abrasive slurries

- Fibrous wastewater

- Food processing waste

- Biological sludge

Multistage Centrifugal Pumps

These pumps generate higher pressure by using multiple impellers in series. They are typically used for moving treated water rather than raw sewage.

Typical wastewater uses:

- Treated water transfer

- Pressure boosting

- Filtration systems

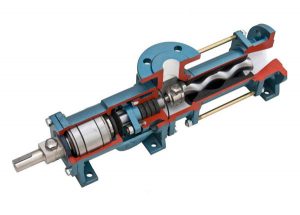

Progressive Cavity Pumps

Ideal for slow, controlled movement of viscous fluids and sludge. They provide consistent flow regardless of pressure.

Typical wastewater uses:

- Sludge transfer

- Thickened sludge

- Chemical dosing (if applicable)

- Dewatering systems

Rotary Lobe Pumps

Designed for gentle handling of viscous fluids and solids without damaging the material.

Typical wastewater uses:

- Sludge transfer

- Thick waste streams

- Industrial effluent

Key Considerations When Selecting Pumps

Choosing the right pump for sewage and effluent systems requires a clear understanding of operational demands:

Fluid Characteristics

Viscosity, solids content, corrosiveness and temperature all influence pump choice.

Installation Distance & Head Pressure

The vertical and horizontal distance fluid must be moved affects required power and efficiency.

Power and Flow Requirements

Proper sizing prevents wasteful energy use and premature wear.

Material Compatibility

Pump materials must resist corrosion and abrasion typical in wastewater handling.

Self-Priming Capability

Especially in wastewater pits, self-priming pumps reduce manual intervention and downtime.

Secondary Factors Affecting Pump Performance

Beyond basic selection criteria, system design and maintenance play important roles too:

- Pipe diameter, length and layout influence flow resistance and efficiency.

- Static lift (vertical distance from suction source) affects priming and power needs.

- Seals, bearings and component quality determine long-term reliability.

- Ease of maintenance and parts availability directly impact downtime.

- Choice of power source (electric, diesel or hydraulic) influences operational flexibility.

Preventative Maintenance: Avoiding Hidden Costs

Poor maintenance often hides in plain sight as increased energy use, unplanned shutdowns or short service life. Regular checks help avoid these issues:

Inspect for Clogs

Solids and debris can block intakes and damage impellers if left unchecked.

Monitor Corrosion & Wear

Rust and surface degradation compromise seals and components.

Watch Noise and Vibration

Abnormal sounds may indicate imbalance or internal damage.

Temperature & Flow Checks

Unexpected heat or fluctuating flow rates point to operational stress.

Seal and Lubrication Care

Leaks often originate from worn seals; correct lubrication prevents premature failure.

Investing in the right pump — and maintaining it properly — delivers reliable performance, lower energy consumption and reduced downtime across wastewater and effluent systems. Careful selection based on fluid type, installation conditions and ongoing maintenance is crucial for sustainable operations.

Related Products